Chris Alvarez and Brendan Foley

Period 5

Period 5

Physics

Mr. Yav

FC Windup

FC Windup

Table of Contents

- Introduction

- Design

- Materials/Bill

- Construction Procedure

- Operation

- Results

- Improvements

- Conclusions

- References

Introduction

Our goal with the mousetrap car was to create a stylish and effective vehicle. Some features that set our car apart include a split mouse trap, a windup pulley, and Lego monster truck wheels. It's main design goal is to optimize acceleration and speed. By splitting the mousetrap, we let the spring rotate many the FC Windup is 747 g heavy.

The goal of this project is to create a vehicle fit for jousting, and one that will allow the egg to survive. The car is also awarded for accelerating the fastest, as the first one to the bottom will win if the vehicles never collide. Our goal is to get our egg to the bottom first.

Design

Our initial designs and our final product turned out significantly differently, due to finding new mousetrap car technology, and re-evaluating our designs.

In our initial design, our vehicle would have seven wheels, one in the front, four smaller ones on the sidecar, and two in the back. Due to foreseen stability issues, this idea was scarped. We also thought about using rubber bands to hold potential energy, but after research, we found that a pulley system could store a lot more, and it may even be easier to make. However, during the brainstorm session, we agreed that the car should take up as much space as possible. In a collision, the more massive our vehicle is, the more energy is transferred into the smaller car. We also agreed that we should use smaller wheels. Our wheels have just a 4 cm radius, significantly smaller than a majority of the competitions' CDs with a 6 cm radius. Our decision to use Lego wheels was also based on how good their traction is, and we trusted it more than putting balloons over CDs.

Our final design uses a pulley system, that turns our mousetrap car into a windup car. Extensive details of how you can manufacture your own are in the Construction Procedure. This windup/pulley method allowed our car to accelerate throughout its entire run, unlike other mousetrap cars. It was also able to store significantly more potential energy. The FC Windup was the fastest mousetrap car out of any other class period, traveling 1.5 meters in just .86 seconds.

Although it's over the recommended $15 budget, Nearly all these materials can be found at home, with exception to the wood, which I took scraps from my work in the theater tech shop. The only products that were bought were the tubing, mousetraps, and race car wheels, for a total cost of $17.65, very marginally over budget.

After assembly, carefully windup the car. Keep the string on the wheel attached to the axle. This entire ordeal was done so that you could turn the spring more times than possible with a standard mousetrap car. This stores significantly more potential energy in the spring, because it's been turned more times, and it's under greater tension. The wheels create a lot of friction due to traction, but the engine is strong enough to overcome the losses (assuming you wind it more than 1.5 times. Any less is only equal to, or less powerful than a standard mousetrap car). The tension from the spring is transferred through the string down to the wheels at the bottom. You get to keep all the energy, as if you installed the bottom wheels correctly, the string should fall off the wheel, and allow the car to continue without stopping due to not having enough string. Only friction (or running into another object) will stop it. You'll also notice this car is somewhat heavy, so dropping it could be very bad for it. Due to its weight, and top speed, it has a lot of momentum. By taking the mass of the vehicle (747 g) and multiplying it by our top speed of 1.74 m/s, the momentum of the FC Windup at top speed is .82 kg m/s. With all that in mind, it looks like you're ready to race!

Initial Design

In our initial design, our vehicle would have seven wheels, one in the front, four smaller ones on the sidecar, and two in the back. Due to foreseen stability issues, this idea was scarped. We also thought about using rubber bands to hold potential energy, but after research, we found that a pulley system could store a lot more, and it may even be easier to make. However, during the brainstorm session, we agreed that the car should take up as much space as possible. In a collision, the more massive our vehicle is, the more energy is transferred into the smaller car. We also agreed that we should use smaller wheels. Our wheels have just a 4 cm radius, significantly smaller than a majority of the competitions' CDs with a 6 cm radius. Our decision to use Lego wheels was also based on how good their traction is, and we trusted it more than putting balloons over CDs.

Final Design

Materials/Bill

Fortunately, many parts of our vehicle were free, due to having them in our possession already. That said, here is the estimated cost of everything:

25 cm x 18 cm Luan chasis: Free, approx. worth $.18 (per sq. cm)

4 Lego monster truck wheels and axles: Free, approx. worth $.15 each

Other scrap wood for supporting the axles (50 cm): Free, approx. worth $.06

Model Race Car Wheels for pulley system, one set with a 4 cm radius, the other with a 2 cm radius: $13 total

Spool of string: Free, approx. worth $3

Mousetrap 4 pack: $2.50

Random Hardware (2 hex nuts and a washer): Free approx. worth $.44

Brass and Aluminum Tubing: 2.15

Total: $21.93

Although it's over the recommended $15 budget, Nearly all these materials can be found at home, with exception to the wood, which I took scraps from my work in the theater tech shop. The only products that were bought were the tubing, mousetraps, and race car wheels, for a total cost of $17.65, very marginally over budget.

Construction Procedure

Time for the fun part: how to make your own.

- Assemble all materials! I'm sure you can find many of them around home. Also, Check Home Depot or other workshops for scrap wood. Hobby shops have the race car wheels, but they're expensive. Any wheel with exterior rims to keep the string on the wheel will do. Worst case, wait until hobby race car wheels go on sale. They're probably not worth getting at full price like I had to. Also, this will require the use of power tools. Access to a paddle drill, and a hand saw will be required at minimum, along with wood glue. Access to a table saw and a chop saw would be far easier though. Wire cutters are also necessary.

- First, you'll need to defuse your mousetrap. First, remove the spring from the hammer, then clip the hammer off. Carefully secure the spring, or hold the trap against something, and cut the spring free from the trap. This is do-able without hurting the spring. Do not cut the spring. Only everything around it. You will not need anything except the spring and the board (for classy aesthetics).

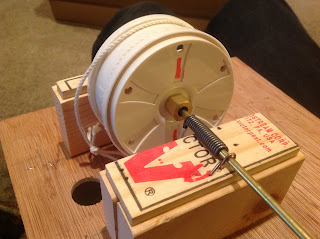

- Now that the spring is free, carefully set it aside. Using your hand saw, cut the board so that where the spring originally was just fits on one side, and cut the portion where the rest would hang off. This separates the board into an approximately 1/6 portion of the board, and a 5/6 portion of the board. Save both pieces. This is a picture of how it will look finally installed.

- Now, cut some luan for the chassis. Cut it to 25 cm x 18 cm. This can be done very easily on a table saw.

- Relatively low on the board, use a paddle drill to make a small hole. Later, the string pulley will run through here. The picture above shows how it should all line up with the hole. This portion does not have to be too specific, the bottom needs to line up, the top does not necessarily. It just looks nicer if it is lined up.

- Now, cut your wood blocks. Three at 10 cm x 5 cm, and four at 7.5 cm x 6.25 cm. Cut them width wise on a table saw before length wise on a chop saw. I did this with 1 x 6, but it's do-able with any material. In the bottom four blocks, put a 1/8 in hole, 5 cm down the pieces. This allows the wheels to be put here.

- Now, use wood glue to attach them. Allow them 5-10 min. to dry, so that the wood is unmovable. Make sure that you keep the blocks straight. I did the bottom four before the top two. Make sure to keep a lot of room (about 5 cm) between the back two blocks, and I kept the front two blocks somewhat close (about 1.5 cm), which will keep the vehicle going straight.

- Once all of them are attached, put a Lego axle through the holes, covered in the brass tubing. For the back, put the smaller, 2 cm radius on the axle. In this wheel, cut out a small tooth, that the string can be attached to.

- Next install the front wheels, axle also covered with brass tubing. Great work so far, you have the chassis nearly finished!

- Back to the top of the car, install the top three blocks, not too far from the hole you cut earlier. The blocks should be about 6.5 cm apart. Two of them on one side of the divide, right next to each other, one block on the other.

- Now, retrieve the spring you had from earlier, along with the board from the trap. Attach the larger board to the two blocks, and the smaller portion of the board to the single block.

- Now, put the wheel on another piece of brass tubing, surrounded by the hex nuts and washer on the small block side.Put the spring through the trap here as well, and use a small piece of the aluminum tubing to attach the long part of the spring (the one that wasn't originally attached to the board) to the wheel, after putting small holes in the wheel if yours did not come with them. I cut extra into mine, but I would not have needed them. However, cut a small hole on the inside of the wheel, and put some string through it.

- Now, wrap the string around the larger wheel so you have just enough for 2 and a half rotations around it, and make a loop at the end, to catch on the tooth of the smaller wheel. Drop the string into the hole, and attach to the lower wheel. Be sure to keep tension on the string.

And that's it! You should now be ready to windup the car. Be sure that the string stays on the wheels, and not the axles, you can actually break your car if you don't. You can just use your finger to guide it back to the wheel. Do not wind too much though. I made my .86 seconds time with about 3 rotations.

Operation

Results

The FC Windup did phenomenally well in the 1.5 m drag race, finishing in just .86 seconds. To solve for our acceleration, we can take the 1.5 m, and divide it by .86 seconds. This means the average velocity was 1.74 m/s (which was used previously in the momentum problem). This velocity, divided by the time (.86 seconds) again gets us the acceleration of 2 m/s/s.

As for its performance in the joust, it did poorly. The FC Windup went 1-2. The egg broke nearly every run. Let's discuss what could have changed its win ratio.

Improvements

Two main problems with our vehicle was the egg's driving seat, along with the lack of a crumple zone. Despite running tests with a placeholder in the driver's seat, the mousetrap car with the egg would hit the bottom of the ramp without evening out. At the bottom. Simply put, the car would hit a wall after going down a ramp, instead of being able to push forwards. Although this could not have been entirely prevented/predicted due to running successful tests prior to jousting day, counter weights on the back, or changing the distance of the wheels away from each other on the board could have changed the results significantly. Alternatively, raising the suspension could also have been beneficial, but that would have required significantly different materials. Secondly, a better crumple zone would have been good. Due to a group miscommunication, the crumple zone was never installed, either in tin foil, or balloon form. We believed our vehicle was massive enough to run over the competition, but due to the lack of egg protection, and the oddities involved with not being able to go down the ramp correctly, we were unable to.

Conclusion

Although our vehicle did poorly in the jousting portion, despite successful tests, it won the drag race. So although we did not make a very good vehicle for jousting downhill, we made a very effective drag racer. In a head-on collision, our egg would have been safe, and in future races, the vehicle could be modified for downhill death matches.

References

"Joustrapcar 2015-16" Mr. Yav. Powerpoint.